AutoCAD 2023 Crack + Product Key

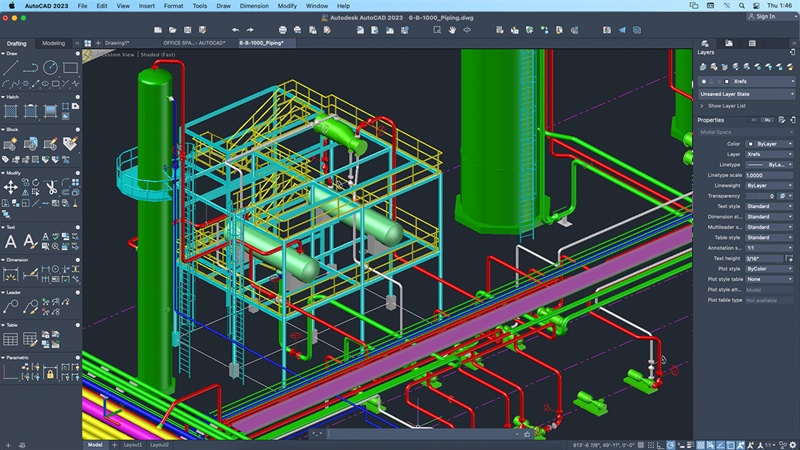

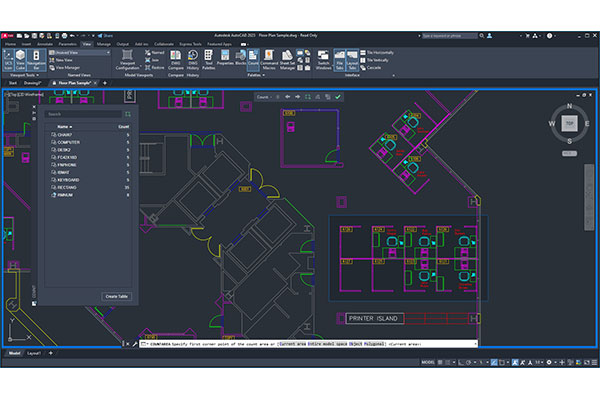

AutoCAD 2023 Crack creates a personalized workspace to maximize productivity with complementary apps and APIs. Autodesk provides download and installation instructions for home users and administrators. Your available downloads will appear in your Autodesk Account or on the training website. Find your product, and choose a version, platform, language, and download method. Visit the Autodesk Knowledge Network for information. The AutoCAD free trial lasts 30 days and offers the possibility to test all the functions of the latest versions for a limited period.

To cancel a free trial, turn off auto-renewal before the trial period ends. If you did not enter a payment method at the start of the trial period, the trial period will automatically expire. Once the trial period AutoCAD 2023 Serial Number expires, you cannot extend the trial period. For short-term needs, you can purchase a monthly subscription and turn off auto-renewal (to limit paid subscription duration to just one month), or purchase Flex Tokens for a flexible pay-as-you-go plan.

We create software that today’s businesses use to innovate, large and small. Join us and contribute to the future of design. Autodesk is changing the way the world is designed and made. Spanning architecture, engineering, construction, product design, manufacturing, media, and entertainment, our technology empowers innovators around the world to solve challenges big and small. From greener buildings to smarter products to stunning blockbusters, Autodesk software empowers innovators to design and create a better world for everyone.

you may also like this AutoCAD 2022 Crack

AutoCAD 2023 Crack Features

- But we look forward to doing more.

- At Autodesk, we don’t believe in waiting for progress.

- We believe in creating it by combining technologies, unleashing talent, and gaining insights.

- And empowering our customers to find solutions to challenges. we face today.

- Our software gives customers the right tools to work with, and the ability to think flexibly.

- And the power to transform what really needs to be manufactured in the world.

- Manufacturing technology can streamline design to meet pressing capacity needs healthcare

- At a time when the nation’s healthcare infrastructure is strained by the COVID-19 crisis, Alabama-based.

- BLOX is industrializing the complex task of building hospitals.

- The company uses manufacturing AutoCAD 2023 License Key technologies to rapidly build acute care medical facilities across the.

- States across the United States – manufacturing components in a factory, transporting them to the construction site, and assembling them on site.

- With a flexible and integrated cycle of design, manufacture, and construction.

- BLOX’s approach to building modular hospitals serves as a model for expanding the capacity of a stressed healthcare system.

- In 2000, Chris Giattina was the lead architect for GA Studio and was hired by a Japanese automaker.

- To design and build an employee training center in Alabama in just nine months.

- Six weeks after the first meeting, the company laid the groundwork, and the project was delivered on schedule.

- With the automaker providing the necessary resources. It was a revelation for Giattina.

- Who noticed the huge gap between the efficiency of the auto industry and the change-resistant American construction industry?

AutoCAD 2023 Crack System Requirements

- In 2010, that aha moment led to the birth of BLOX, an Alabama-based design, and manufacturing.

- And construction company that uses a modular design to modernize old-fashioned building practices.

- Giattina, now President of GA Studio and CEO of BLOX.

- Leads the BLOX team in designing and building healthcare facilities from scratch in a fraction.

- Of the time required by traditional construction without compromising cost or quality.

- “We focused on healthcare because we urgently needed to figure out how to get a good product on the market.

- BLOX started by prefabricating smaller standard components.

- Such as ceiling brackets, surgical AutoCAD 2023 Serial Key brackets, and hospital bed headboards with electrical.

- And medical gas systems, and bathroom modules with plumbing fixtures.

- “We first learned how to make small, complicated things, then we moved on to making small buildings,” says Giattina.

- “Imagine a nested Russian doll: we make a small part that fits into a larger part.

- Which in turn fits into a larger part and eventually fits into what’s called a supermodule, which is the biggest thing you can ship on a highway.”

- The Uber module – 15 feet wide, 15 feet high, and 60 feet long – can encompass.

- An entire trauma center or a series of spaces such as labs, imaging rooms, patient rooms, and even break rooms.

- The BLOX team uses a building delivery system they call Giattina Design.

- Manufacture Construct (DMC) “If you think of a continuum then there really is raw material at one end and.

- It is processed in stages progressively until it becomes a building,” he says.

What’s New AutoCAD 2023 Crack

- On the DMC continuum, a building can be made up of any combination of standard components, sub-assemblies, panels, modules, and super-modules.

- Components are designed and manufactured in a controlled factory environment.

- BLOX manufacturing facility in Bessemer, AL using repeatable processes and systems.

- “In a case where we have an increasingly unskilled workforce.

- we are creating systems that allow unskilled workers to do things that previously required skills,” says Giattina.

- “Skilled workers become machine makers” who create AutoCAD 2023 Keygen processes and tools that can be used by other workers.

- The actual hospital construction site then becomes an assembly site and not a more risky conglomeration.

- Of different trades creating a client-specific construction site.

- “At the site, the foundations come in, and then you put these big boxes on top – there might be 20 or 50 going to a site,” says Giattina.

- “Frame them with a kit of parts that could be flat-packed, then assemble walls that have already been factory-made.”

- Some of the BLOX team’s recent projects include stand-alone emergency rooms in Nevada.

- Florida, and Texas for Universal Health Services (UHS); Standard modules for acute.

- Patient rooms in dozens of hospitals for HCA Healthcare; and currently underway, a 170-bed hospital in Nevada.

- By streamlining the construction lifecycle, which goes straight from design to manufacturing.

- Giattina says, “You can build an entire building in about three weeks and have it running.

How to Install it?

- Software and data analysis were essential to the development of a DMC operation.

- BLOX has been a long-time user of Revit to design its building components.

- The next step was to integrate digital designs into the factory manufacturing process via a cloud-based data management system.

- “We go from model to production, and we do it systematically,” explains Giattina.

- “We have developed a platform called WEVR which uses our own software development with Forge and BIM 360.”

- The WEVR platform analyzes data from AutoCAD 2023 Product Key countless government healthcare regulations.

- And clinical practice inputs from healthcare facility staff and management to identify hundreds of design opportunities.

- An algorithm has narrowed down the design options to a few standard designs that meet the stringent requirements of multiple states.

- “At this point, you can make a part that can be used in Reno, Nevada, or Miami, Florida,” he says.

- “Essentially, we use an industrialized process and a data-driven process to develop.

- Best-in-class solutions for components that can be assembled in hundreds, if not infinite, ways,” in healthcare facilities.

- Amid the ongoing coronavirus health crisis, the BLOX factory is in full production with its ongoing hospital projects.

- But the company also plans to use its industrialized construction process to address this.

- One of the most pressing healthcare priorities for cities and states across the United.

- States: is a need for more hospital beds to treat patients with COVID-19. The company adapts its systems to build.

Conclusion

The BLOX MICU would allow medical providers to quarantine patients with COVID-19, preserve existing hospital capacity for other patients, and protect frontline workers from unnecessary exposure. And with COVID-19 hotspots emerging in urban and rural areas, “the first MICUs could be in any location needed,” says Giattina. “You can just as easily AutoCAD 2023 Activation Key switch to one or the other,” as the artificial intelligence (AI) technology and data analytics that power the DMC platform takes into account different state regulatory requirements for hospital establishments. The company’s DMC delivery system helped BLOX meet this unique challenge in an agile way. “We’ve built a team of incredibly smart people: 400 architects, engineers, programmers, makers, contractors,” he says.

“And we’re all working to solve the very, very difficult problems and make our industry better.” When the aging water treatment plant in Toledo, Ohio was flooded with toxic green algae in the summer of 2014, citizens were denied clean water. For days. Following this emergency, the city turned to global design and engineering firm Arcadis to renovate and expand the 80-year-old facility. Using advanced Building Information Modeling (BIM) technology and cloud collaboration, Arcadis designed an upgrade to improve the facility’s resilience and ensure safe water for the community. The company has changed the way it works. On August 2, 2014, residents of the Midwestern, Ohio city of Toledo received a “do not drink” advisory from the Ohio Environmental Protection Agency (OEPA).